Genuine Parts

Original is better

Our certified genuine parts guarantee unmatched quality and peak performance.

Manufactured using the same procedures and materials to FPT Industrial’s rigorous standards: total compatibility, longer service life, and guaranteed operation.

Our certified genuine parts guarantee unmatched quality and peak performance.

Manufactured using the same procedures and materials to FPT Industrial’s rigorous standards: total compatibility, longer service life, and guaranteed operation.

- HOME/

- CUSTOMER SERVICE/

- genuine parts

FPT INDUSTRIAL GENUINE PARTS – THE BEST CHOICE FOR YOUR APPLICATION

FPT Industrial genuine parts offer the maximum efficiency and environmental sustainability for your applications, reducing fuel consumption and emissions. Engineered to match the exact specifications of your original equipment, they are rigorously tested to guarantee your engine’s safety, longevity, and reliability. With global fast delivery and top technical support provided by FPT’s Authorized Workshops, downtime and maintenance costs are reduced, allowing you to keep your operations running in peak condition.

Discover the benefits:

Designed and engineered by FPT Industrial

Top engine’s performance

Full respect of FPT technical specifications

Maximum uptime thanks to parts reliability

12 months warranty coverage

After-treatment System

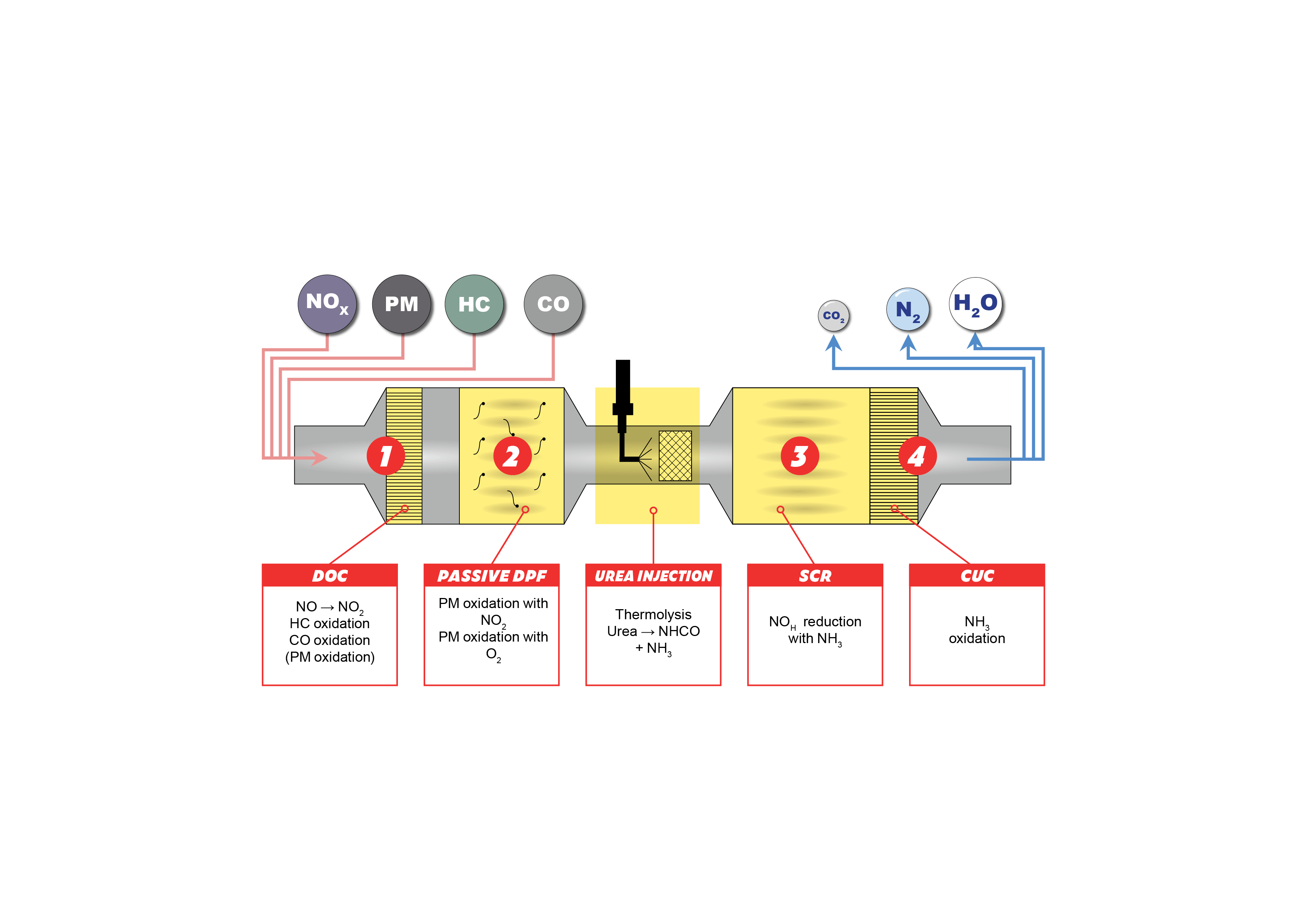

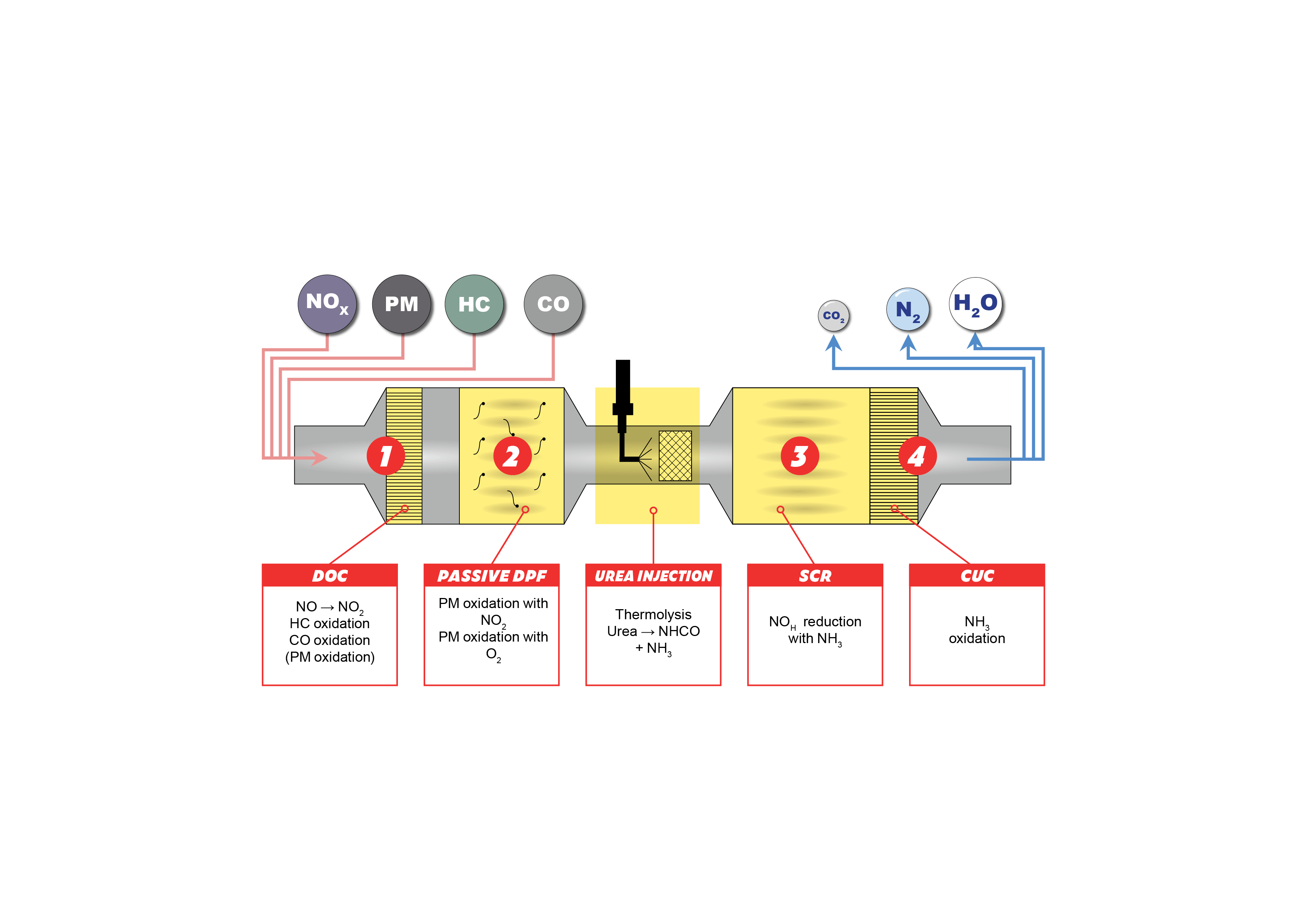

FPT Industrial after-treatment system (ATS) converts the pollutants present in exhaust gases produced by the engine to reduce emissions and ensure compliance with global environmental standards.

HOW IT WORKS

PERFORMANCE

Inside the combustion chamber, Particulate Matter (PM) and Nitrogen Oxides (NOx) have conflicting chemical factors.

A high combustion temperature leads to economic fuel consumption and low particulate (PM) levels, BUT it generates a high rate of Nox production. No Diesel Engine currently can be designed to meet both PM and NOx emission standards without the use of an exhaust treatment system. In either situation, an exhaust aftertreatment system is needed to reduce the levels of pollutants down to the required limits.

Thanks to the ATS system, engineers can develop engines with extremely low fuel consumption while still meeting the emission targets.

A high combustion temperature leads to economic fuel consumption and low particulate (PM) levels, BUT it generates a high rate of Nox production. No Diesel Engine currently can be designed to meet both PM and NOx emission standards without the use of an exhaust treatment system. In either situation, an exhaust aftertreatment system is needed to reduce the levels of pollutants down to the required limits.

Thanks to the ATS system, engineers can develop engines with extremely low fuel consumption while still meeting the emission targets.

WHY CHOOSE AN FPT GENUINE ATS

As the emission legislation becomes more and more severe, it is fundamental that the engine is developed together with its ATS system. FPT develops specific solutions, according to the characteristics and the mission profile each FPT engine has been designed for. Every component of the ATS system has been developed, tested and validated to outstand the most severe conditions and ensure optimal performance and longevity in any working condition of your FPT engine.

GET THE MOST OF AN FPT GENUINE ATS

After a certain amount of suit is built up into the filter, it can be difficult for the gases to exit, and the engine performance can be affected. Make sure to perform a full regenerating cycle when requested. Make sure that your urea tank is filled with certified DEF / AdBlue® additive only. Other fluids, not compliant with DEF specifications, may damage the system and could cause serious damage to your machine. Furthermore, exhaust emissions would no longer meet legal standards.